Mechanisms Relating

to Reducing Stress in Curing

Thick Sections of UV Adhesives.

- Eric A. Norland

and Frank S. Martin

- Norland Products

Inc., North Brunswick, NJ 08902

1. ABSTRACT

Ultraviolet curing adhesives

are widely used in optical lamination of precision optical lenses,

safety windows, holographic displays, and flat panel displays.

In most of these applications they are being used in relatively

thin films from 3 microns to 40 mils, because most formulations

will only allow UV light to penetrate to a certain depth. If the

formulation does cure in thicker sections, the stress due to shrinkage

typically becomes a problem.

UV adhesives have been developed

which can be cured in relatively thick sections with minimum stress.

In this paper, a number of formulations are compared for variations

in stress when cured in thick sections and the conditions and

mechanism to minimize stress are characterized.

2. INTRODUCTION

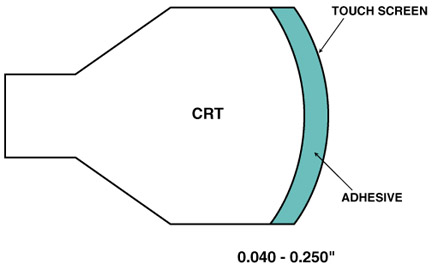

This paper discusses work done

in conjunction with formulating a UV curing adhesive for laminating

touch screens to cathode ray tubes used for computer displays.

CRT's provide a challenging laminating process because of their

large curved face. Problems arise because the tolerance between

the CRT and the touch screen are difficult to match. Some areas

will be in close contact while others may be separated by 1/8

inch.

Manufacturers in the past have

overcome this problem using a thick layer of a slow curing epoxy.

The process entails mounting the touch screen on the face plate

with a thick compressible gasket on at least three sides to form

an enclosed area for filling with adhesive. The gasket which can

be up to 1/4 inch is used to minimize any differences in adhesive

thickness. The epoxy typically cures at room temperature for 24

to 48 hours and compresses the gasket as it draws the two surfaces

closer together.

3. UV ADHESIVE CHARACTERISTICS

A UV curing adhesive was desired

in this application because of the great savings in production

time. But first some considerations of its curing characteristics

had to be made.

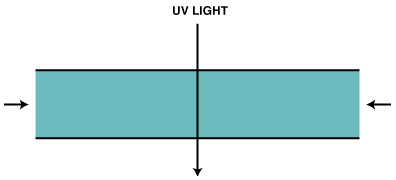

UV curing adhesives are typically

used in thin films, because most do not cure well in thick sections

or if they do, the stress due to shrinkage becomes a problem.

Shrinkage does not always cause

stress if handled correctly. In most UV curing applications the

adhesive cures from the surface down. If there is a uniform bondline

and uniform UV exposure, as the lamination cures, the two surfaces

will be drawn closer together creating very little stress.

If thicker layers are cured,

we can no longer think in terms of linear shrinkage but must consider

it on a volumetric basis, shrinking in all directions. This can

be a problem because UV adhesives cure so quickly that neither

the adhesive or the surfaces can equilibrate fast enough to prevent

stress from occurring.

Drawing on an analogy to epoxy,

it was theorized that if the UV adhesive could be formulated to

allow a more uniform cure throughout the adhesive, similar to

the way a two part epoxy cures all at once throughout the product,

it would have more of a chance to equilibrate itself and minimize

void formation.

Literature describes a number

of photoinitiators that are designed for a depth cure as opposed

to a surface cure. These materials tend to be non-fluorescing

and are very efficient, only absorbing the UV energy that they

need and allowing the rest of the energy to pass all the way through.

Previous experience led to quick identification of a range of

appropriate materials.

4. INITIAL EXPERIMENT

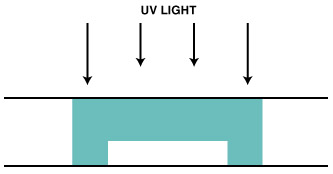

To approximate CRT/Touch Screen

laminations, 4" X 6" glass cells were made using silicone

sealant around 3 sides of the plates to create a 1/8" gap.

<../IMG src="gifs/5.jpg" WIDTH="251"

HEIGHT="237" ALIGN="BOTTOM" NATURALSIZEFLAG="0">

Three UV curing formulations

were tested to find a suitable replacement for the 24 hour epoxy

which had been used. The first was a standard grade low shrinkage

UV adhesive (NOA 61). The second (NOA 73) was a new formulation

designed to cure well in thick sections. The third formulation

(1050-87) was similar to the second except the concentration of

the photoinitiator was decreased to provide a slower cure.

Samples cells were filled with

these UV adhesives and placed in front of a uniform low intensity

UV light (1200 microwatts/cm) for 15 minutes. Low intensity was

used to provide time for the adhesive to equilibrate during the

cure. Cure and shrinkage in the form of void formation was observed

during the exposure. Sample 1 (NOA 61) appeared to proceed smoothly

for the first 5 minutes. But as the cure proceeded to the full

depth of the cell, small areas began shrinking away from the surface

causing large voids to appear. (Illustration 1).

For sample 2 (NOA 73) the results

were much better but again near the end of the process areas at

the surface of the adhesive started to shrink and create voids

at the edges. (Illustration 2).

Sample 3 (1050-87) was exposed

for the same amount of time and showed neither appreciable void

nor stress formation. (Illustr. 3).

All three samples were believed

to have similar shrinkage rates. But sample 3 had been optimized

to minimize potential stress formed during shrinkage. Two further

tests were done to determine what characterized this difference

in the cure.

5. EXOTHERM

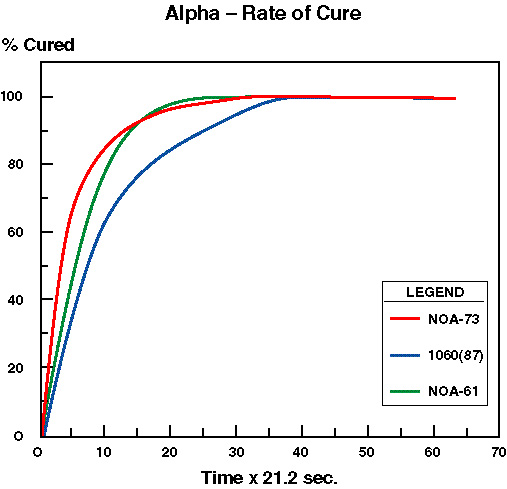

Samples were UV cured using

an intensity of 1500 microwatts/sq. cm of UV light in a Perkin

Elmer Model DSC-7 Differential Scanning Calorimeter. The exotherm

was measured for each sample at 25°C and the alpha, or rate

of reaction, was calculated by integrating the area under the

exotherm curve. Results are shown in graph 1.

Comparing samples 1,2 and 3, each progressively higher sample

shows a broadening of the alpha curve which indicates a slowing

of the cure rate. But the change does not appear to be significant

enough to fully explain the change in cure and stress formation.

It is believed that because only small samples were allowed in

the calorimeter, the test was not appropriate for observing differences

caused by a thick cure.

6. DEPTH OF CURE

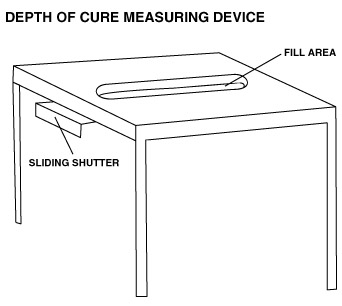

A device was made to allow

measurement of the depth of cure after various UV exposure times.

This would provide data on thickness as a function of the rate

of cure. The device was composed of a 1/2" x 6" cutout

in a plastic substrate that was 5/8" deep. This was supported

on two sides with 8" legs. A clear cellophane tape was attached

to the bottom of the cutout to form a mold that could be exposed

from below. A sliding shutter was installed underneath the cutout

to allow the length of the mold to receive different exposure

times.

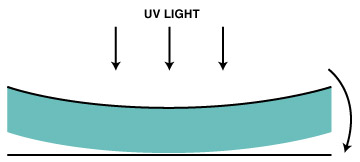

25 gms. of the UV curing adhesives

was placed in the mold and centered over a fluorescent black light

emitting 1000 microwatts/sq. cm of UV light. The entire length

was exposed for 30 seconds before the shutter was moved to block

1" of the mold. Exposure times were doubled for each consecutive

exposure with the shutter moving another 1" each time. Exposure

intervals were 30 sec., 1, 2, 4, 8, and 16 minutes.

After completion of the cure

cycle, uncured adhesive was poured off the top surface and a gentle

acetone wash was used to rinse away any uncured liquid left. The

sample was removed from the mold and thickness measurements of

the different exposed segments were made.

The resulting data is shown

in graph 2, which shows a drastic difference in the formulations.

With the low intensity UV light the first sample was never able

to cure to more than 50 mils. The thickness increased at a steady,

proportional rate to the exposure time indicating a cure from

the surface toward the center.

Sample 2 showed a much more

efficient through cure for the same exposure time. Total thickness

was over 200 mils and the thickness increased steadily in proportion

to the exposure time.

Sample 3 showed the most difference. Total

thickness was the highest for this material, averaging over 250 mils, but the

shorter exposures did not have an appreciable effect on film forming. Film thickness

was not measurable until 120 seconds of exposure at which time it was close

to 250 mils. It appears that the cure was occurring uniformly throughout the

film on initial exposure but was not sufficient to fully polymerize the material

until a certain minimum exposure had occurred.

It was also found that the

total thickness reaches a maximum at 240 seconds, in the middle

of the cure cycle, and then begins to shrink. This is a further

indication of a more uniform through cure in which the polymerization

occurs on a constant basis and the entire thickness shrinks at

the end of the cure cycle.

7. CONCLUSIONS

It has been shown in this set

of experiments that minimizing stress in curing thick sections

of UV adhesives requires the ability of the formulation to cure

throughout the thickness at a relatively uniform rate as opposed

to curing from the surface down. The proper choice of the reactive

polymers, photoinitiators, and UV light intensity, can all be

optimized to provide an efficient through cure.

8. REFERENCES

1. Baeumer, W., "Selection

criteria for photoinitiators," Kontakte(Merck),1989(3),42.

2. Ohngemach, J. and Neisius,

K.H.,"Curing by UV radiation," Kontakte(Merck), pp 15-20,

March 1980

Home

-

Adhesives -

Fiber Optics -

Fish Gel -

Distributors -

About -

Trade Shows -

Employment

|