|

|||

|

|||

Norland Optical Adhesive 87

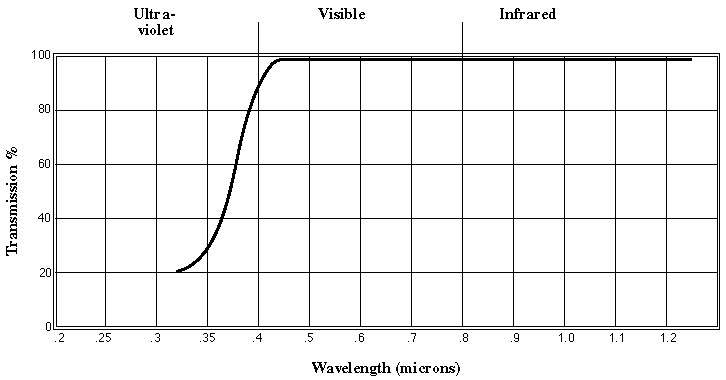

Norland Optical Adhesive 87 is an adhesive that will cure optically clear when exposed to long wavelength ultraviolet or visible light (blue-violet). The adhesive has low viscosity and meets the Bellcore specifications of 85C/85RH for 750 hours. NOA 87 is recommended for bonding glass or plastics. This adhesive can be cured by ultraviolet light between 315 to 400 nanometers and visible light between 400 to 420 nanometers. The peak absorption wavelengths are 325, 365 and 400 nanometers. Minor absorption wavelengths are 410 and 420 nm. Full cure requires 3.5 Joules/cm 2 .

When fully cured, NOA 87 has very good adhesion and solvent resistance, but it has not reached its optimum adhesion to glass. This will come with aging over a period of about 1 week in which a chemical bond will form between the glass and adhesive. This optimum adhesion can also be obtained by aging at 50 0 C for 12 hours.

NOA 87 can withstand temperatures before aging from -15C to 60C when used for glass bonding. After aging, it will withstand temperatures from -125C to 125C.

Typical Properties of NOA 87

Refractive Index |

1.52 |

Temperature Range (after aging) |

-125C to 125C |

Viscosity @ 25C |

900-1500cps |

| Elongation at Failure | 13% |

| Modulus (PSI) | 209,700 |

| Tensile Strength | 4,880 |

Hardness - Shore D |

50 |

(Measured through a bond thickness of 1 mil.)

Bond thickness 1 mil

Shelf life of the liquid is a minimum of 6 months from the date of shipment, refer to the package label for the actual expiration date, if stored in a cool (5-25° C), dark place in the original container. If refrigerated, allow the adhesive to come to room temperature prior to use.

Care should be taken in handling this material. The Material Safety Data Sheet should be read for this product. Prolonged contact with skin should be avoided and affected areas should be washed thoroughly with copious amounts of soap and water. If adhesive gets into eyes, flush with water for 15 minutes and seek medical attention.

The data contained in this technical data sheet is of a general nature and is based on laboratory test conditions. Norland Products does not warrant the data contained in this data sheet. Norland does not assume responsibility for test or performance results obtained by users. It is the users responsibility to determine the suitability for their product application, purposes and the suitability for use in the user's intended manufacturing apparatus and methods. The user should adopt such precautions and use guidelines as may be reasonably advisable or necessary for the protection of property and persons. Nothing in this technical data sheet shall act as a representation that the product use or application will not infringe a patent owned by someone other than Norland Products or act as a grant of a license under any Norland Products Inc patent. Norland Products recommends that each user test its proposed use and application before putting into production.