|

|||

|

|||

Light Sources

The Norland collection of long-wave, ultraviolet light sources have been carefully selected to fit all of your bonding needs when using Norland Ultraviolet Curing Adhesive. Whether you are bonding lenses, tacking electronic components, or curing optical splices, these lights are designed to cure the adhesive quickly and safely. Special features and designs have been added to some of these lights so that they work together with the Norland UVC Optical Splice. To decide which light source is best for you, here are some points to consider. First is the size of your bonding area. It is critical that the entire adhesive area receives uniform light to insure proper curing. Second is the thickness of the adhesive. The thicker the bond line, the higher intensity of UV light is required to cure the adhesive. The third consideration is cure speed. Higher intensity lights will cure the adhesive faster but have more potential for causing strains. Lower intensity lights cure slower but tend to minimize strain in the bonded area.

Multi-Pole LED UV Curing System

To

buy the Multi-Pole LED click here >>

The Multi-Pole LED UV Curing System emits a consistent and repeatable 2.5 W/cm squared @ 365nm at each pole. Unlike lamp technology there is no lamp or liquid light guide degradation or UV intensity variables throughout the individual poles. The 50,000 hour life of the LED and lack of liquid light guides and replacement lamps brings to the forefront of UV technology a zero level “cost of ownership”! The LED Multi-Pole system is equivalent to a 10 W/cm squared lamp system using a 4 pole liquid light guide.

The Opticure LED Cube II (p/n 5100-II) is an enclosed UV oven that has UV LED modules which generate a wavelength of 365 nm. The Cube reduces stress when bonding larger optical parts because the

LEDs do not heat the curing area. The Cube cabinet is made of aluminum. The interior has special UV reflectors which create a uniform illumination of the curing area. A deluxe Opticure LED Cube II

(p/n 5102- II) is also available and emits up to 39 milliwatts/cm2 has a N2 purge with O2 level detection for triggering cure cycle, and a three level turn table.

Tray cure area: UV energy at tray level.

Top Tray:

11.7” wide x 13.1” depth x 5.5 “ high 14,000-16,000 microwatts /cm2

Middle tray:

11.7” wide x 13.1” depth x 9.4” high 8,000-10,000 microwatts /cm2

Bottom tray:

11.7.” wide x 13.1” depth x 11.8” high 5,000- 6000 microwatts /cm2

Digital Timer: Can be set from 1 second to 99 hours.

To buy the LED CUBE >>Call for Pricing

NEW

The Norland Opticure UV/VIS Wand is a first of its kind light source. Less expensive than our LED 200, it is both a UV and visible light curing system that uses powerful light emitting diodes as its light source. This portable handheld unit is powered by a rechargeable lithium ion battery. The Opticure UV/VIS Wand has a UV and visible energy output up to 1.8 watt/cm 2 and can emit 365nm /385nm light , 405nm /420nm light or a combination of both. It gives a cure area of ½” at ½” distance from your bond area. A microprocessor provides control of timing, audible indicator, temperature sensing, and battery management. An LCD on the wand provides a read out of selected time exposures of 1 to 60 seconds. The LCD also displays the battery discharge level. The unit can be manually turned off at any time by pressing the start button a second time after your initial start. The Opticure UV/VIS Wand includes the light source, two rechargeable lithium ion batteries. Cradle charger with pass/fail radiometer port, power supply, anti-glare shield and UV blocking glasses.

To

buy the Opticure UV/Vis Wand click here >>

Opticure LED 200

The Norland Opticure LED 200 is a powerful UV curing system that uses a powerful light emitting diode as its light source. This ergonomically designed, portable, hand held unit is powered by a rechargeable lithium ion battery. The Opticure LED has a UV energy output at full power of 2.5 W/cm squared at 365nm. A microprocessor provides control of timing, audible indicators, temperature sensing, exposure time, and battery management. An LCD on the back of the light source provides a read out of selected time exposures of 10,20,30,40,50,60 seconds and 3 minutes. The LCD also displays the battery discharge level. The unit can be manually turned off at any time by pressing the trigger a second time after your initial start. The Opticure LED UV curing system includes a light source, two rechargeable lithium ion batteries, battery charger, light source stand, UV blocking glasses and carrying case. This light source is CE approved.

To

buy the Opticure LED 200 click here >>

Traydex 18 & 45 UV and Visible Light Curing Ovens

Fast curing low volume broadband LED UV/visible curing ovens. The Traydex 18 has a cure area of 5"L x 7"W x 5.5" H and generates 5.8 milliwatts/cm2 of UV and visible energy from 375nm to 470nm and the Traydex 45 has a cure area of 5.5"L x 5.5" W x 6.2"H and generates 13.9 milliwatts of UV and visible energy from 375nm to 470nm.

To

buy the Traydex 18 Light Curing Ovens click here>>

To

buy the Traydex 45 Light Curing Ovens click here>>

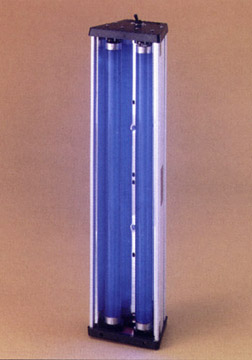

Spectronics Bench Mount

To

buy the Bench Mount Lamp click here >>

The Spectronics Bench Mount Lamp style XX-15A (P/N 5600) is ideal for slow, even cures over a large area. Two 15 inch bulbs are housed in a rugged anodized aluminum housing. On the inside of the housing is a specular aluminum reflector to maximize the UV irradiance. This lamp has sturdy metal brackets so that the lamp can easily be mounted overhead. The XX-15A uses two 15 watt bulbs (P/N 5611) and typically peaks at 2,000 microwatts/sq. cm when mounted at a distance of 4 inches. The cure area of this unit is approximately 4 x 15 inches.

Splice Lamp

To

buy the Splice Lamp click here >>

The Splice lamp (P/N 5200) is a table top lamp especially designed for curing the Norland UVC Optical Splice. This 4 Watt, high intensity, fluorescent black light (P/N 5211) is mounted in a sturdy, hinged stand that can be lifted out of the way during assembly and then lowered into place for the cure. The splice lamp has a cure area of 1.5 x 2 inches. The average light intensity of this unit is 2,500 microwatts/sq. cm at a distance of 1.5 inches.

Cure time for Norland UV Adhesive

When bonding two surfaces with Norland UV Adhesive, the minimum full cure is estimated at 20 times the precure time using the same intensity of ultraviolet light. This is a general statement that works well in most applications.

The precure time is defined as the time it takes to initially set or gel the adhesive so that the two surfaces being bonded can no longer be moved. For example, a 15 second precure requires 5 minutes (15 seconds x 20 = 5 minutes) for full cure. Typical precure times will be from 5 seconds to 60 seconds depending on light intensity and adhesive formulation. When different light sources are used in production for the precure and the full cure, the precure time used in this calculation must be measured using the full cure light source.

| Light Source |

Cure Area |

Intensity (microwatts/sq. cm) |

Recommended Distance |

4 Pole Multi-Pole LED |

0.5" diameter |

10,000,000 |

0.5 inches |

| Opticure CUBE | 6.7" to 11" | 5,000-12,000 |

5.5 to 13.82 inches |

| Opticure UV/Vis Wand | 0.5" diameter | 1,800,000 | 0.5 inches |

Opticure LED 200 |

0.5" diameter |

2,500,000 |

0.5 inches |

Traydex 18

|

5"x7"x5.5" |

5,800 |

5.5 Inches |

| Traydex 45 | 5.5"x5.5"x6.2" | 13,900 | 6.2 inches |

|

Splice Lamp |

1.5" x 2" |

2,500 |

1.5 inches |

|

Bench Lamp |

4" x 15" |

2,000 |

4 inches |

Safety

Ultraviolet light is commonly divided into two regions. Short wave UV in the 190 to 320 nanometer range and long wave UV in the 320 to 400 nanometer range. The short wave UV is considered the most dangerous because it can easily damage the eye and can cause sun burn. No short wave UV light is emitted by any of the Norland UV light sources.

Long wave UV is considered relatively safe. There have been studies that show that high intensity long wave UV and bright visible light up to 500 nanometers can cause damage to the eyes with prolonged exposure. Because Norland UV Adhesives cure so quickly, our UV lights are low to medium intensity and are extremely safe to use with minimal precautions. Do not stare directly at the light and wear UV blocking eye protection. Indirect light from these units is considered relatively harmless.

Home - Adhesives - Fiber Optics - Fish Gel - Distributors - About - Trade Shows - Employment