|

|||

|

|||

Norland Optical Adhesive NOA 146H is a clear, colorless, liquid photopolymer that will cure when exposed to ultraviolet light and/or heat. Since it is a one part system and 100% solids, it offers many advantages in bonding where the adhesive can be exposed to UV light. The use of NOA 146H eliminates premixing, drying or heat curing operations common to other adhesive systems. Curing time is remarkably fast, and is dependent upon the thickness applied and the amount of ultraviolet light energy available.

NOA 146H is designed to give the best possible optical bond when using plastic to plastic or plastic to glass substrates. NOA 146H has excellent adhesion to CR-39, polarized film, Delrin®, nylon, cellulose acetate butyrate, polycarbonate, acrylics and glass.

NOA 146H also has excellent clarity, low shrinkage and a slight flexibility that make it superior to other materials for optical bonding. These characteristics are important in order for the user to produce high quality optics and achieve long term performance under changing environments.

NOA 146H is cured by ultraviolet light with maximum absorption within the range of 320-395nm. The peak absorption wavelengths are 325 and 365 nanometers. The recommended energy required for full cure is 4.5 Joules/cm squared.

In most optical applications, UV curing is done in two steps. A short, uniform exposure, or precure, is used first. The precure time is of sufficient duration to set the bond and allow it to be moved without disturbing alignment. This is followed by a longer cure under UV light to obtain full cross-linking and solvent resistance of the adhesive. The precure can be obtained in 15 seconds using a 100 watt mercury lamp at 6". Where longer time is required for alignment, it can be extended to a few minutes using a very low intensity light source. The final cure can be accomplished in 5 to 10 minutes using the 100 watt mercury lamp.

The precure allows the user to align and set the precision parts quickly and minimizes the number of holding fixtures required. After the precure, excess adhesive can be wiped up with an alcohol or acetone moistened cloth. Assemblies should be inspected at this time and rejects separated in methylene chloride. The bonded area must be soaked in the solvent and normally will separate overnight. The time required to break the bond depends upon the extent of the cure and the size of the bond area. Caution should be taken when using methylene chloride as it dissolves many plastics.

In addition to the UV cure, NOA 146H contains a latent heat catalyst that can quickly cure areas that do not see the ultraviolet light. The catalyst allows the adhesive to cure in 10 minutes at 125°C in a convection oven, or 3 hours at 80° C. Faster cure times are possible with infrared ovens. Areas in contact with air will cure tacky unless exposed to UV light or given the 125° C cure. Temperatures less than 60°C will not appreciably activate the adhesive. The advantage of the heat cure is to bring partially cured adhesive to full cure to get the maximum physical properties of the adhesive. The heat cure is not required if all the adhesive receives proper exposure to UV light.

Typical Properties of NOA 146H |

|

Refractive Index |

1.46 |

Temperature Range |

-15 C to 90° C |

Viscosity @ 25C |

40 cps |

Shelf life of the liquid is a minimum of 4 months from the date of shipment, refer to the package label for the actual expiration date, if stored in a cool (5-22° C), dark place in the original container.If refrigerated, allow the adhesive to come to room temperature prior to use.

Care should be taken in handling this material. The Material Safety Data Sheet should be read for this product as well as for any associated products such as alcohol, acetone or methylene chloride. Prolonged contact with skin should be avoided and affected areas should be thoroughly washed with copious amounts of soap and water. If the adhesive gets into the eyes, flush with water for 15 minutes and seek medical attention. Use the material in a well ventilated area, otherwise a NIOSH approved organic vapor mask is recommended.

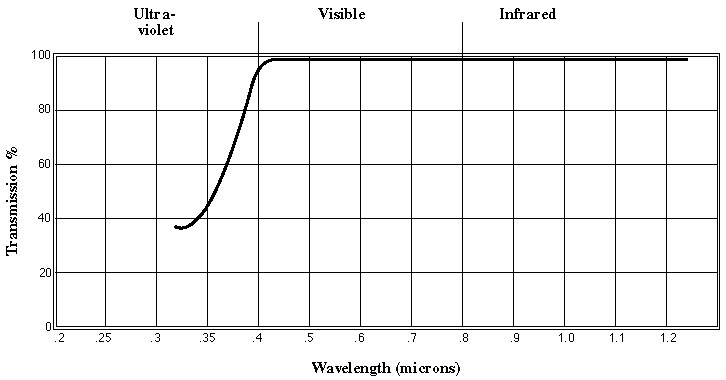

Spectral Transmission NOA 146H

The data contained in this technical data sheet is of a general nature and is based on laboratory test conditions. Norland Products does not warrant the data contained in this data sheet. Norland does not assume responsibility for test or performance results obtained by users. It is the users responsibility to determine the suitability for their product application, purposes and the suitability for use in the user's intended manufacturing apparatus and methods. The user should adopt such precautions and use guidelines as may be reasonably advisable or necessary for the protection of property and persons. Nothing in this technical data sheet shall act as a representation that the product use or application will not infringe a patent owned by someone other than Norland Products or act as a grant of a license under any Norland Products Inc patent. Norland Products recommends that each user test its proposed use and application before putting into production.

[Click Here To View SDS Information]